overview

This project was a Senior Capstone Project for the Mechanical Engineering program at UC San Diego. It was a collaboration among Ishan Duriseti, Juan Carlos Garcia, Kaleb Ugalde, and myself, with the generous sponsorship and mentorship of Garrison Leach, MD, a resident in the UC San Diego School of Medicine Department of Plastic Surgery.

Senior capstone group project aimed at reducing the cost of microsurgical instruments to expand training accessibility in low- and middle-income countries.

Utilized additive manufacturing, sheet metal design, and computer-aided design optimization. Demonstrated significant cost reduction and functional similarity through mechanical characterization and qualitative testing.

core competencies

- Design Optimization, Design of Experiments

- Biomedical Instrument Design

- Additive Manufacturing, Design for Manufacturing

Low-Cost Design for Selected Microsurgical Instruments (Jeweler Forceps, Dilator Forceps, Microneedle Holder)

introduction

Microsurgery is a surgical specialization that utilizes a microscope to perform precision operations on small, delicate structures—such as blood vessels, nerves, and tissue. Microsurgery is a specialty of plastic surgery and commonly utilized in reconstructive and transplant surgeries.

Microsurgery is a rapidly growing field but access to is limited in low- and middle-income countries (LMICs) due to the lack of training and significant equipment cost.

How can we reduce the cost of microsurgical instruments to enable training of microsurgeons in low- and middle-income countries?

Reconstructive microsurgery being performed.

Image Credit: Leica Microsystems.

design approach & analysis

Hybrid Construction: Low-Cost “Hybrid Material” design reduces manufacturing complexity and utilizes low cost materials.

- Handles: 3D‑printed or injection‑moldable plastic with reinforced geometry

- Tips: laser‑cut 410 stainless steel, heat‑treated to ~45 HRC.

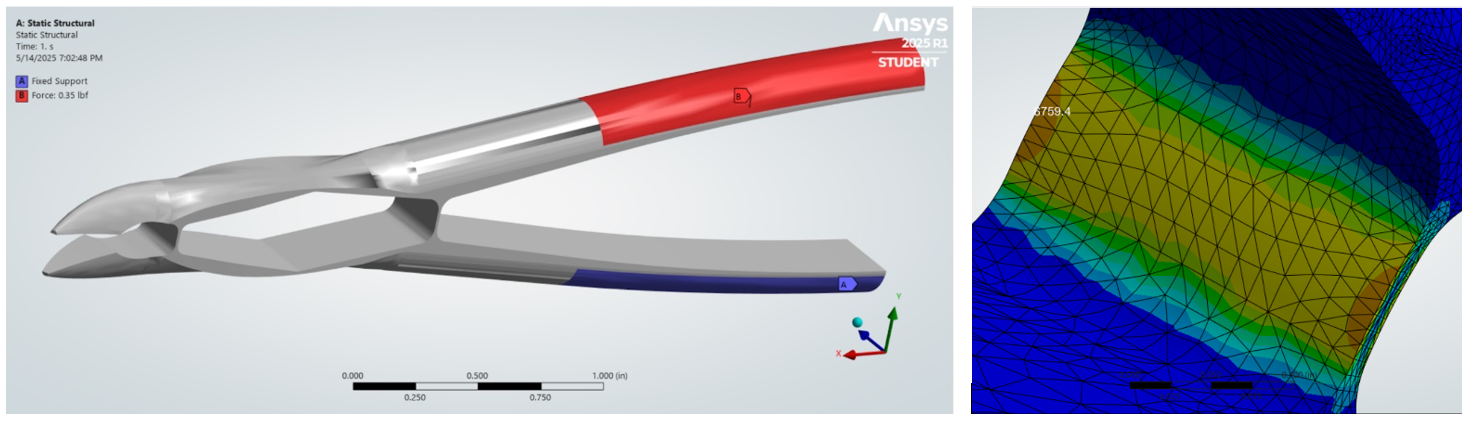

Analytical Modeling: ANSYS FEA to optimize handle

thickness, flexure patterns, and hinge designs. ANSYS static structural FEA guided incremental updates—adjusting thickness, rib placement, and flexure geometry—to tune the deformation under simulated finger pressure.

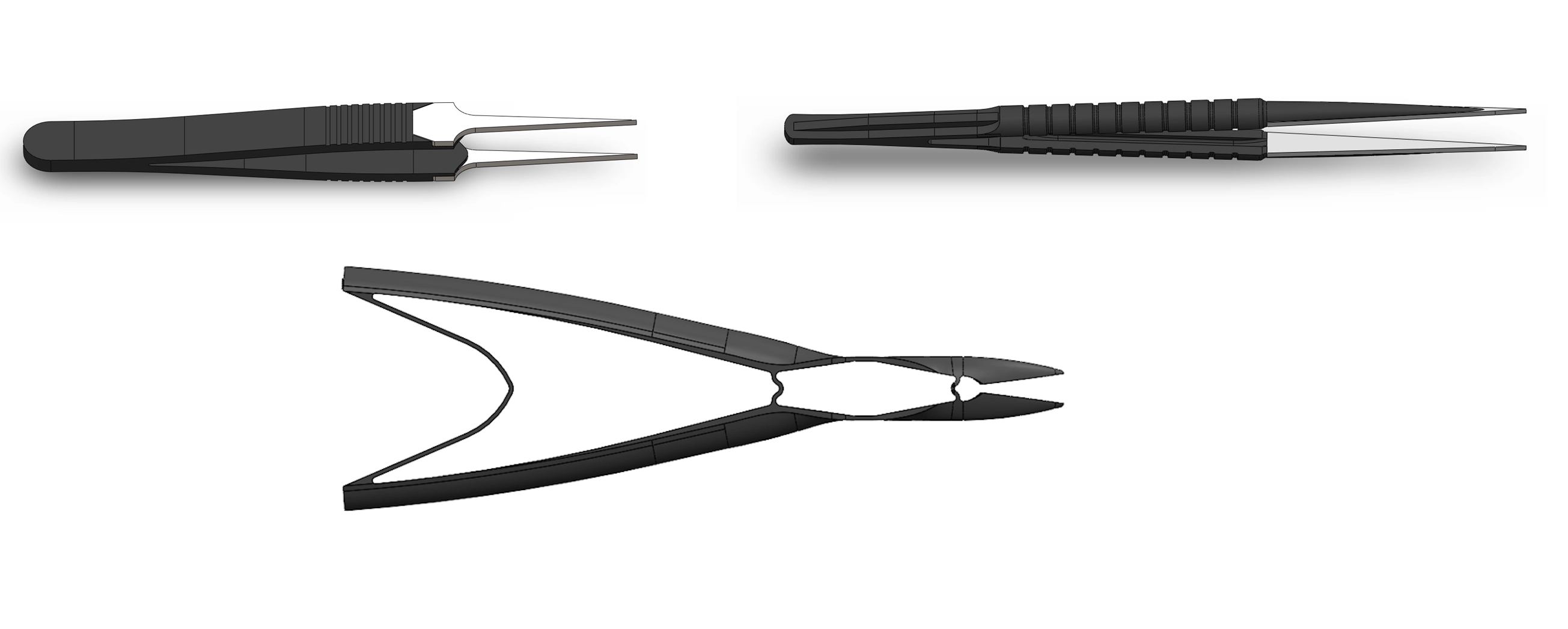

Low-cost, hybrid construction design architecture.

Analysis analysis for the microneedle holder.

prototyping

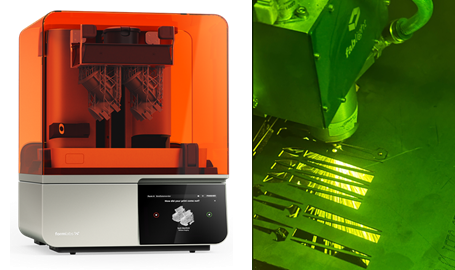

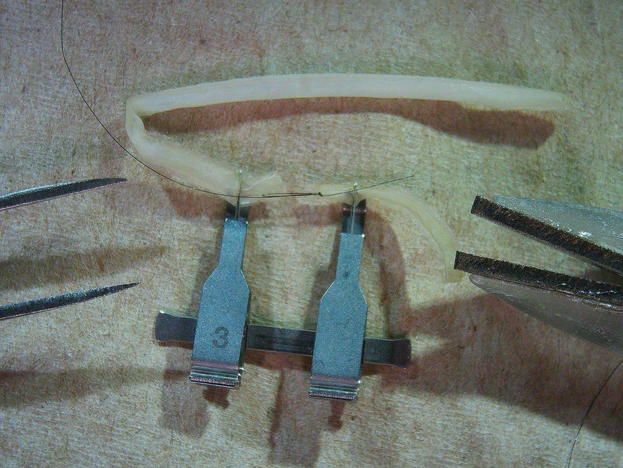

All prototypes were produced by masked stereolithography (MSLA) printing on a Formlabs Form 4, enabling rapid design iterations of handle geometries and hinge details. The printed handles were paired with hand‑finished, 410 stainless tips cut on a Fablight FL4500 to match OEM geometry and functionality. Handles and tips are joined with printed alignment features and bonded with a cyanoacrylate adhesive.

Jeweler and Dilator Forcep Prototypes

Formlabs Form 4 and Fablight FL4500

testing & validation

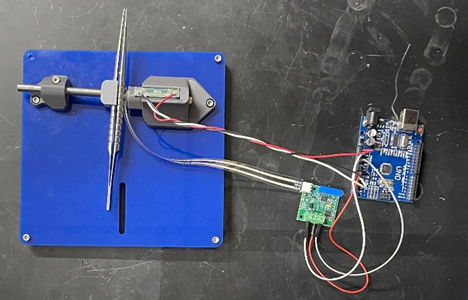

Prototypes underwent mechanical characterization on a test rig, where force–deflection curves of the low-cost prototypes were directly compared against OEM benchmarks. Additionally, five practicing microsurgeons evaluated the prototypes, providing ratings on tactile feedback, control precision, ergonomic comfort, assembly quality, and similarity to standard instruments. Average scores ranged from 3 to 4 out of 5, with constructive suggestions guiding final refinements.

Custom test rig for mechanical characterization.

results & impact

Utilizing the hybrid construction approach is a viable method to produce single-use, disposable low-cost microsurgical instruments for training. Our prototypes cost less than $1, up to 99.86% cost reduction, compared to OEM surgical tools while maintaining the same form, fit, and function. This significantly expands the accessibility of microsurgical training to LMICs.

This design also provides a framework for the production of low-cost microsurgical instruments on a large scale (> 10,000 units per year) by utilizing injection molding, roller-die sheet metal processes, and economies of scale to further drive down cost.

Prototype tools successfully perform simulated end-to-end vascular anastomosis.