overview

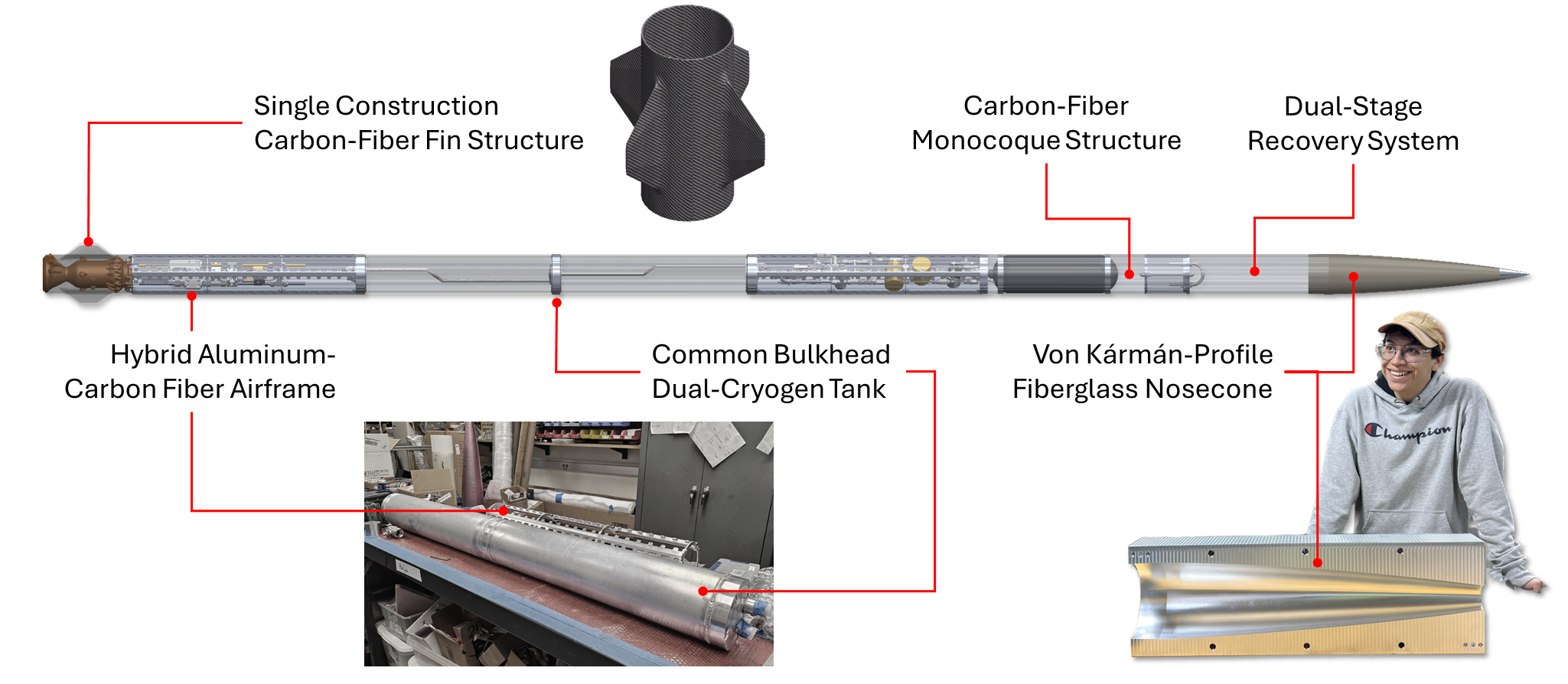

Halya is rocket developed by a project team at SEDS UCSD, a group dedicated to the development of industry-level projects at a collegiate level. Halya is a student researched and designed (SRAD) liquid bipropellant sounding rocket. It is powered by liquid methane and liquid oxygen ("methalox") and has a predicted apogee of 30,000 ft AGL.

As Lead Structures Engineer, I led a team of 10 engineers in the primary research and development of all structural systems for the rocket, including high-level system architecture design and system integration.

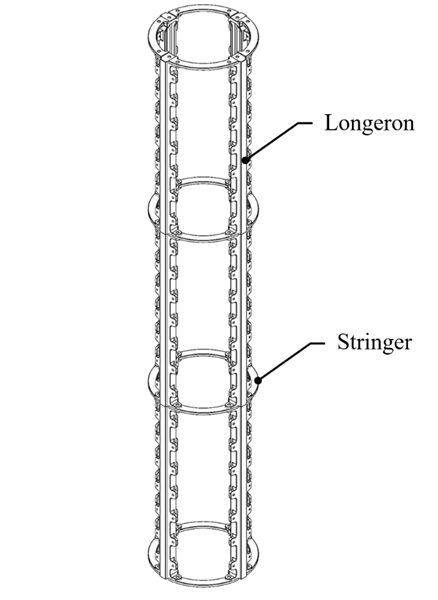

As an individual contributor and Responsible Engineer, I designed, built, and tested the hybrid aluminum-carbon fiber airframe. Edward Yu, the Halya Analysis Lead, and I co-authored a paper, presented at AIAA SciTech, on the development of the aluminum "longeron-stringer" aspect of the airframe.

During my time on Halya, I was also responsible for the structural bulkheads and led efforts in composites development and other rapid prototyping.

core competencies

- Leadership, Technical Management, Research

- Engineering Design/Analysis/Optimization

- Full Cycle Hardware Development

- Design for Manufacturing and Assembly, GD&T

- Mechanical Testing and Data Analysis

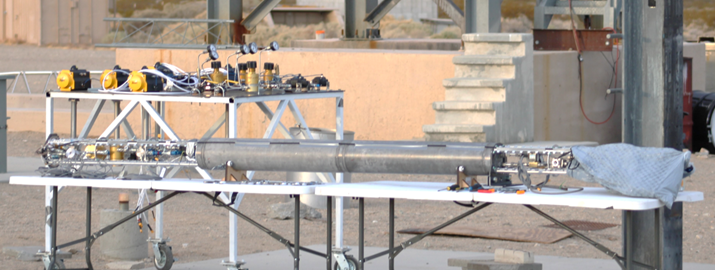

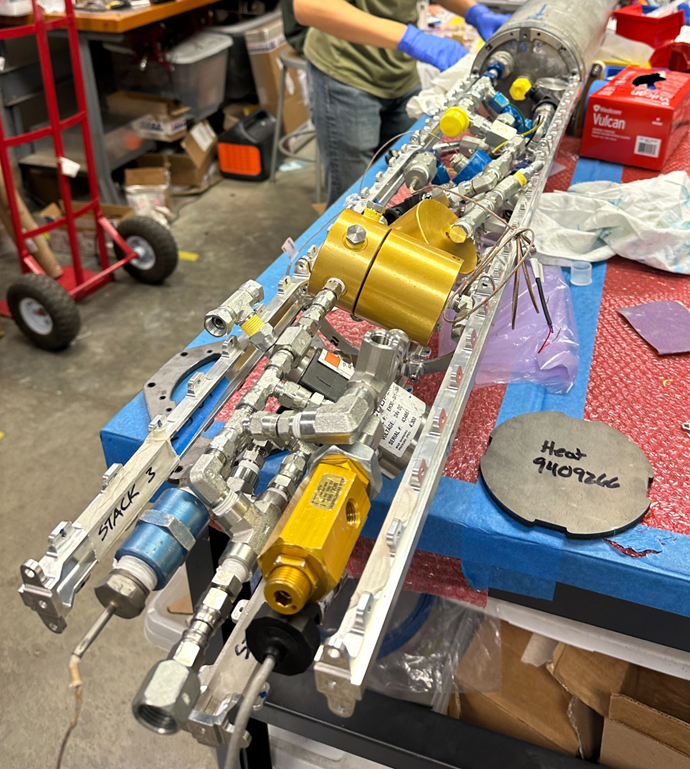

Integrated Halya primary structure during fluid system testing.

Halya model and design highlights.

background

Halya is an extremely ambitious rocket. It is powered by SEDS UCSD's most powerful and first methalox engine, Nephas, which is capable of a maximum thrust output of 2000 lbf.

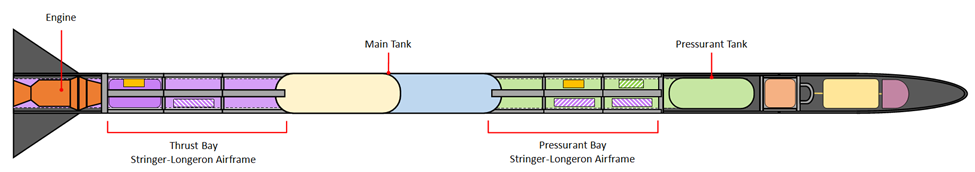

Halya is designed to compete in the FAR-MARS Launch Contest, a challenge to develop an highly optimized rocket to reach 45,000 feet with a strict impulse limit. This required Halya to be a state-of-the-art, innovative design and sees the debut of many structural improvements, including a longeron-stringer airframe.

SEDS UCSD's first methalox engine, Nephas, during a hotfire test.

airframe design

System design of the Halya, highlighting the longeron-stringer airframe sections used to house the propellant feed systems.

CAD model of the longeron-stringer airframe section.

Physical prototype of the longeron-stringer airframe section.

analysis & testing

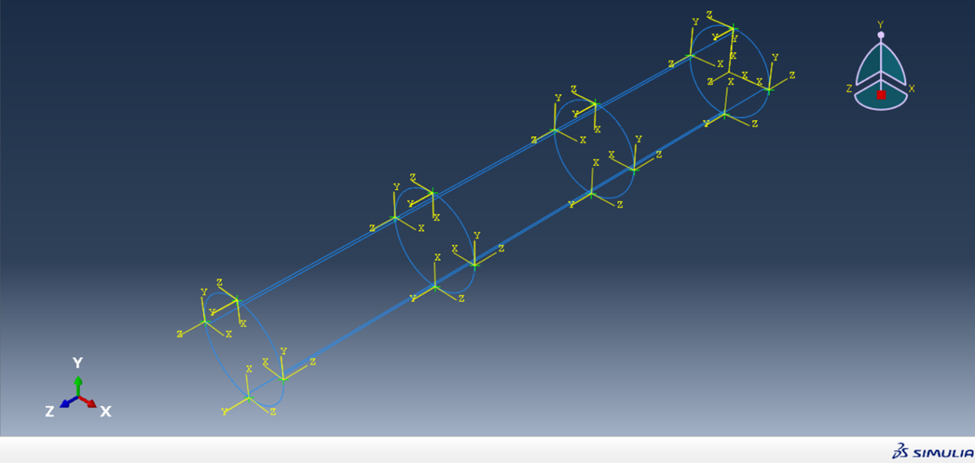

Reduced beam-element ABAQUS model of the longeron-stringer airframe for eigenvalue buckling stability analysis.

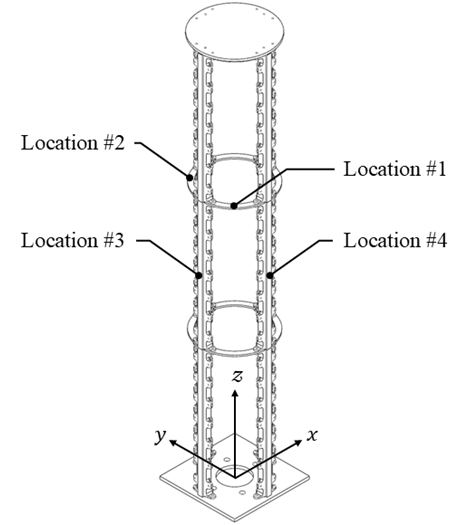

Locations of the strain gages on the longeron-stringer airframe.

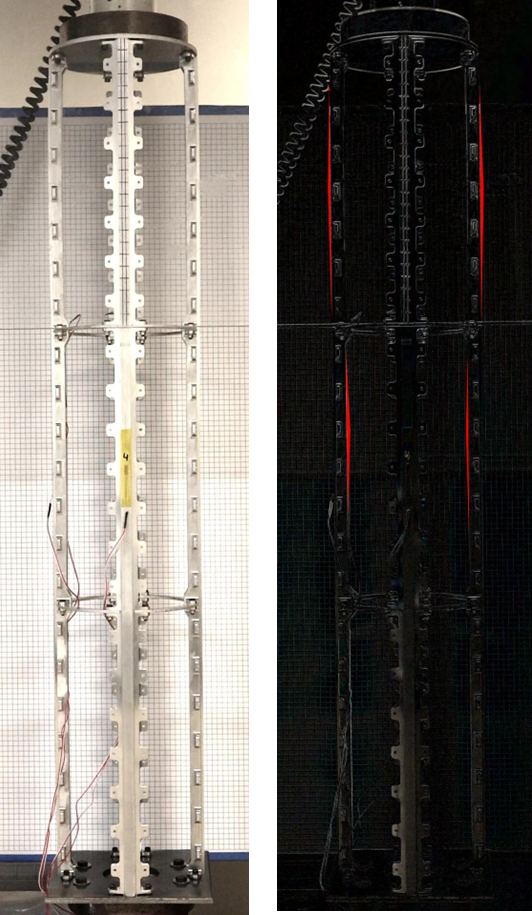

Testing setup of the airframe, with strain gages attached, mounted in the Instron load frame

results

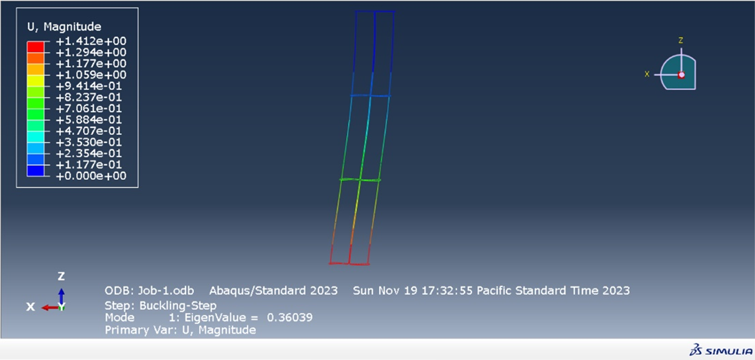

First mode of buckling predicted by the ABAQUS simulation.

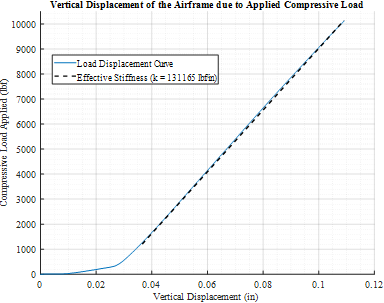

Load-displacement behavior of the airframe under compressive loading.

Final displacement at 10 kips (left). Out-of-plane displacements at load highlighted in red (right).

Photograph of Halya fluid system integrated within the longeron-stringer subassembly.